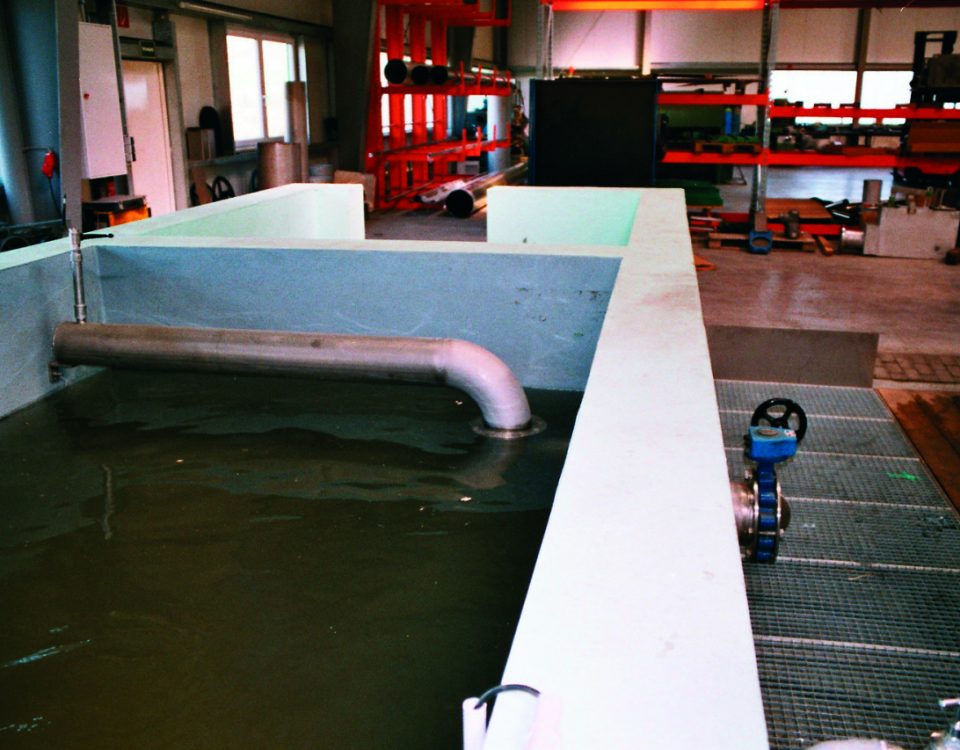

The new technology of dirt freight retention for rain relief (rain overflows)

Dirt brake (APA-SB)

The new technology of dirt freight retention for rain relief (rain overflows)

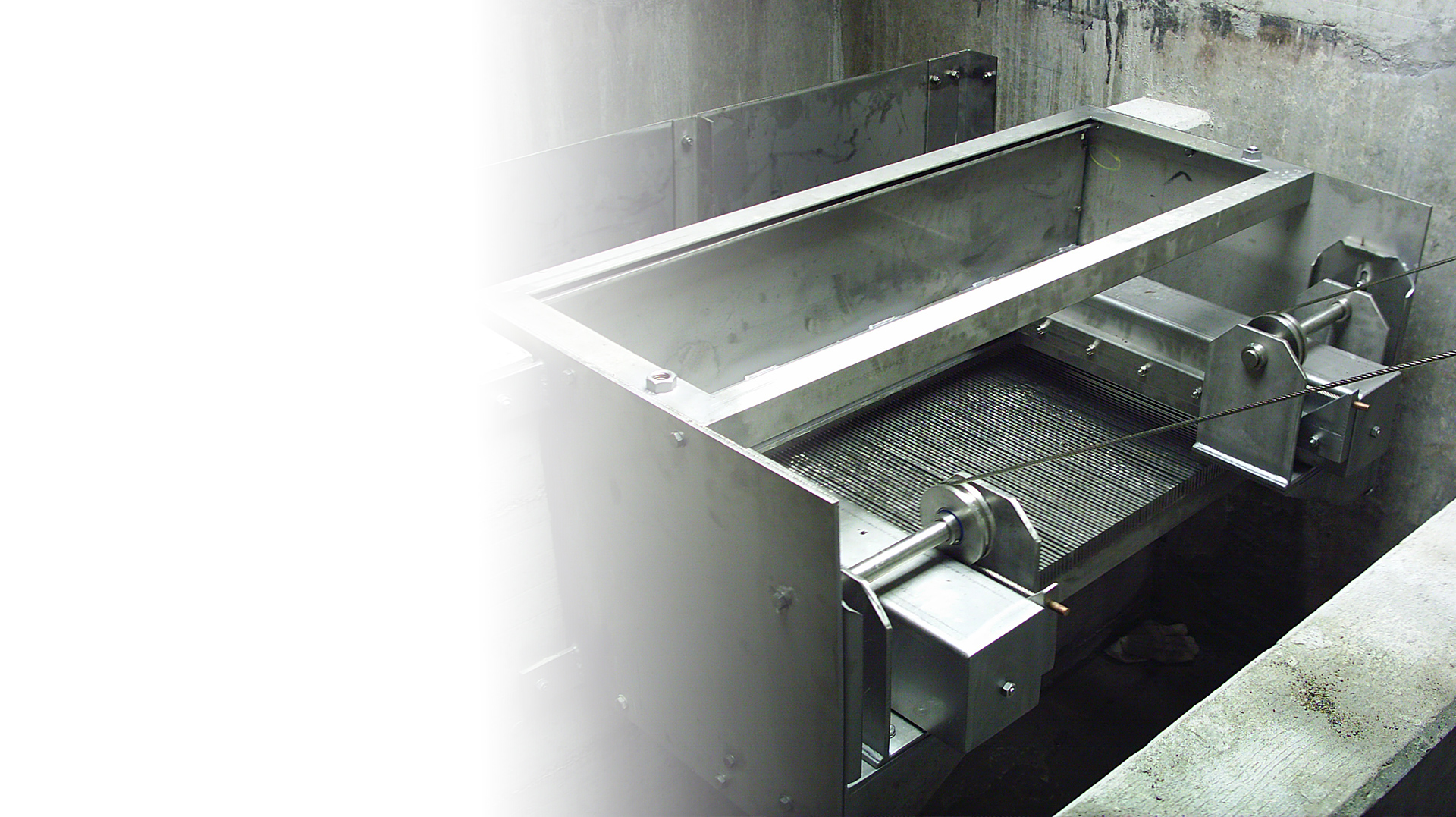

The dirt brake is designed in such a way that at a given water level the scraper exchange blade moves into the relief position and releases a corresponding discharge cross-section of the screen lamellas.

When the blades are laid, the relief cross section continues to open accordingly.

This results in a sensitive behaviour between the laying of the slats to the open relief cross section and the inflow water quantity. When the maximum water level is reached and the maximum opening stroke of the scraper replacement blade is reached, the maximum efficiency of the dirt brake is reached. If larger quantities of water run in, they are fed to the receiving watercourse via the emergency relief dam shield. The rake and the emergency relief plate are preceded by a baffle.

As the water level drops, the scraper deflector blade moves forward to the mixed water channel due to the weight of the deflector blade counterweight. The contaminants are transported to the mixed water channel via the rake combs on the scraper deflector blade. The pollutants remain in the sewer to the sewage treatment plant. In the event of high water from the receiving watercourse, the dirt brake remains closed as long as the water level in the reservoir is below the threshold height or the specified reservoir target.

The dirt brake, in its sophisticated design, offers the following advantages over conventional screening systems.

High operational reliability due to

- large storage space for the dirt freight retention

- simple technique

- no external energy required

- purely mechanical

- strong clearing force at the end of rainfall

- no energy costs